PVC, or polyvinyl chloride, is a commonly used material in the electrical industry for its excellent insulation properties. PVC can be found in various electrical applications, such as wires, cables, and electrical tape. PVC electrical insulation is known for its durability, flexibility, and cost-effectiveness, making it a popular choice for many industries.

Butyl Tape Wrapped Up

Temperature Rating: 90°C

How Does It Work?

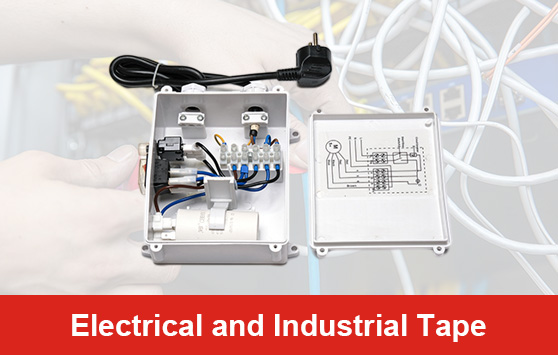

No matter what kind of control box you’re designing, it’s important to follow the established best practices of control box design . Some of the core principles of designing a great control box are as follows:

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.

electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.Anyone who’s left a roll of general purpose vinyl tape in the cab of their truck on a very hot summer day can attest to the fact that heat makes the adhesive soft. Extreme heat makes it ooze and flow.

self bonding rubber tape. Simply stretch the tape around the object, overlapping the layers to ensure a tight seal, and the adhesive properties of the tape will bond to itself, creating a strong, durable connection. The tape can be easily cut to size with scissors or a knife, making it customizable for any application.

There are several types of polyethylene film, each with a different density and use. Polyethylene tape is categorized by the tape’s density:

33 kv ht insulation tape.

Electrical control panel equipment like circuit breakers and switchgear is another common application for electrical control boxes. A breaker box needs to resist environmental conditions that might damage the sensitive electrical equipment inside.

Butyl seal tape is much easier to work with than the traditional sealants used for windows, so many people prefer to use it. It is incredibly supple and easy to bend and manipulate to the shape of the surface you’re using it on, making it ideal for installation on oddly-shaped windows and window frames.